Why Mines Struggle with Siloed Data Between Mine and Mill

Why Mines Struggle with Siloed Data Between Mine and Mill

In today's data-driven mining landscape, the seamless integration of information across the mine-to-mill value chain is paramount. Yet, many mining operations grapple with fragmented data systems that hinder efficiency and decision-making. This article delves into the challenges posed by siloed data and explores strategies to overcome them.

The Challenge of Siloed Data

Data silos occur when information is isolated within departments or systems, preventing holistic analysis and collaboration. In mining, this often manifests as disconnected datasets between geological surveys, drilling operations, and milling processes. Such fragmentation can lead to:

-

Inefficient Operations: Without integrated data, aligning drilling activities with milling schedules becomes challenging, leading to suboptimal throughput.

-

Delayed Decision-Making: Accessing and reconciling data from disparate sources slows down critical decisions, impacting productivity.

-

Increased Costs: Redundant data management systems and manual data reconciliation efforts escalate operational expenses.

As noted by Databricks (2023), siloed data reduces visibility and access across teams, introduces operational inefficiencies, and increases governance complexity.

Real-World Implications

Consider a large-scale copper mine in Latin America that faced significant variability in daily mill throughput rates. The root cause was traced back to siloed data across six different systems covering geological models, drilling patterns, and process plant sensors. By integrating these datasets into a unified analytical model, the mine achieved a 5–10% improvement in mill throughput and a ~10% reduction in mill power draw (Rovjok, 2023).

Similarly, a case study by Cognizant (n.d.) highlights how a cloud-based AI analytics solution enabled mine operators to monitor throughput and efficiency by identifying the root causes of lower yields in near real-time, leading to improved operational performance.

Strategies to Break Down Data Silos

-

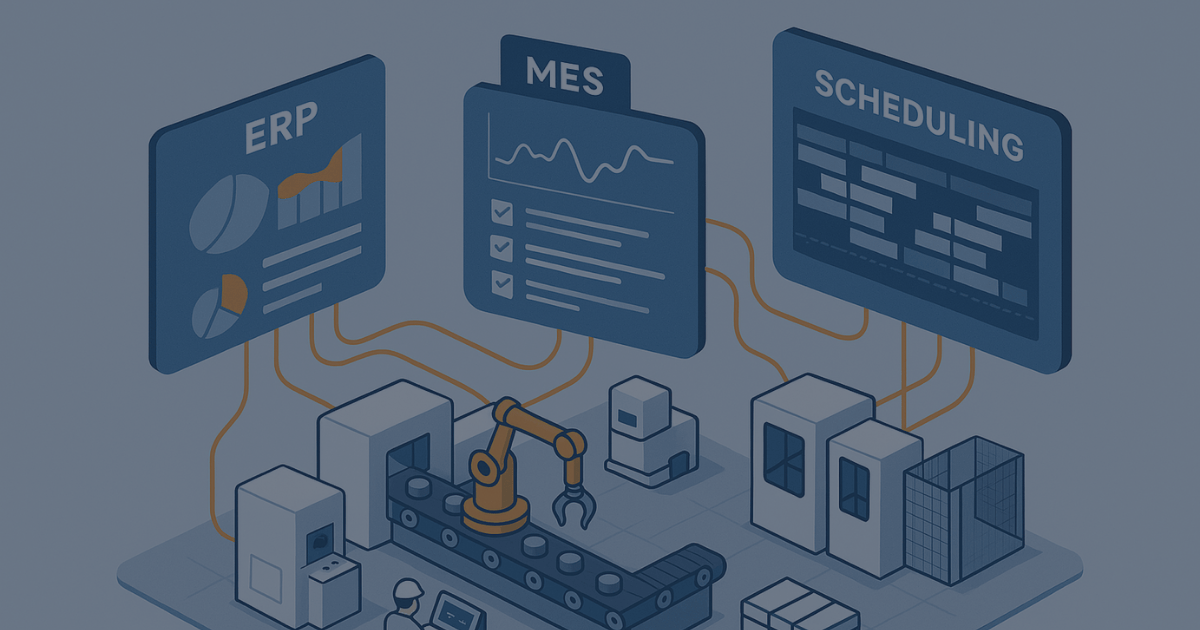

Implement Integrated Data Platforms

Adopt centralized data warehouses or lakehouses that consolidate structured and unstructured data, facilitating seamless access and analysis (Databricks, 2023). -

Standardize Data Formats

Ensure consistent data formats and protocols across departments to enable interoperability and reduce reconciliation efforts. -

Foster a Collaborative Culture

Encourage cross-departmental collaboration and data sharing to break down organizational barriers. -

Leverage Advanced Analytics

Utilize machine learning and AI tools to analyze integrated datasets, uncovering insights that drive operational efficiency (Kohezion, n.d.).

At NTWIST, we’ve built our platform around these very principles - empowering industrial operations with integrated, AI-driven solutions that eliminate silos, enhance visibility, and deliver actionable insights in real time. Our work with mining operations has shown that bridging the gap between mine and mill isn’t just possible - it’s profitable.

Conclusion

Siloed data between mine and mill operations presents a significant barrier to efficiency and profitability. By embracing integrated data strategies and fostering a culture of collaboration, mining companies can unlock the full potential of their operations, driving innovation and sustainable growth.

References

Databricks. (2023, May 2). Data Silos Explained: Problems They Cause and Solutions. Retrieved from https://www.databricks.com/blog/data-silos-explained-problems-they-cause-and-solutions

Rovjok. (2023). Mine-to-Mill Analytics and Mill Optimisation. Retrieved from https://rovjok.com/casestudy/mine-to-mill-analytics-and-mill-optimisation/

Cognizant. (n.d.). Cloud-Based AI Analytics Solution for Mining—Case Study. Retrieved from https://www.cognizant.com/us/en/case-studies/mining-cloud-based-ai-analytics

Kohezion. (n.d.). Siloed Data: What is Data Silos, Problems and Solution. Retrieved from https://www.kohezion.com/blog/siloed-data